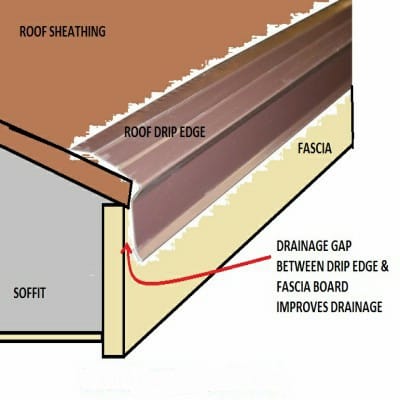

4 - If you prefer to email a sketch you can use this field, otherwise, leave blank.You may also upload a sketch and leave this field blank. 5 Types of Drip Edges on Metal Flashings Drip edge can be found on many metal flashings and components that are installed on your roof system, including: Gutter apron Rake edge flashing Gravel stop Chimney caps Coping The outward projecting lower edge in this picture is what is referred to as a drip edge. 3 - This is where you'll enter dimensions for fields A, B, C, D & E.Provide dimensions needed and angles if needed on field 3. 2 - Material Stretch-out: Pick the appropriate selection for the amount of stock material needed.Įxample: If adding all dimensions of your custom profile (A+B+C+D) equals 11.5", you'll pick the next size up, for example, 12" stock.Material: 24/26 Gauge 304 Stainless Steel 2B FinishĪll dimensions are approximate with ~1/8" tolerance.The most commonly used material for this style masonry drip edge is 26 gauge 304 2B finish, but 316 alloy as well as 24 gauge or even thicker may be purchased as a special order.įor modified profiles, send us an email with a sketch for a quote. Our masonry flashing features a 0.5" kick with a 0.375" closed hem but can be customized to different sizes. Drip edge comes in various forms depending on the style of the roof it is installed with and is designed to prevent water from collecting under a shingle roof. This simple thru wall flashing profile is used to divert moisture trapped inside a wall to the outside in an effort to avoid damage. Drip edge is an industry term to describe flashing that protects the edge of the roof deck from water damage. Thorough Wall Masonry Flashing Metal with Drip Edge - 10' Length Available in Stainless Steel, Galvanized Steel and other materials as special order.

0 kommentar(er)

0 kommentar(er)